WE HAVE THE SKILLS AND TECHNOLOGY TO FULLY MANUFACTURE FROM PROCESSED PARTS TO MECHATRONICS PRODUCTS

• Design

• CNC Machining

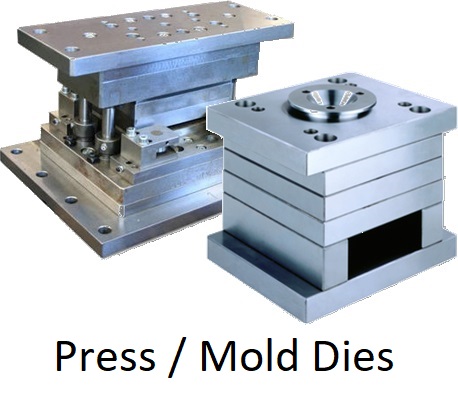

• Die Repair and Maintenance

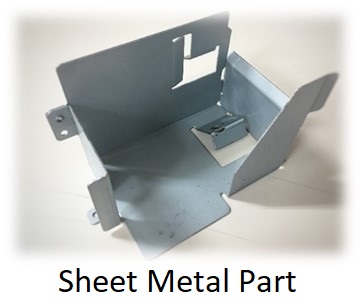

• Sheet Metal

- Press Stamping

- CNC Laser/NCT

• Plastic Molding

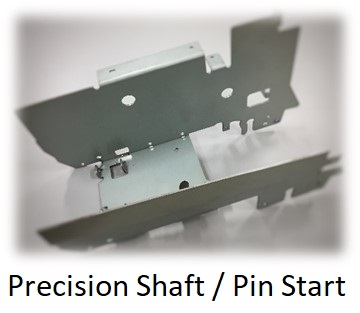

• Precision Shaft/Pin

• On-going Establishment

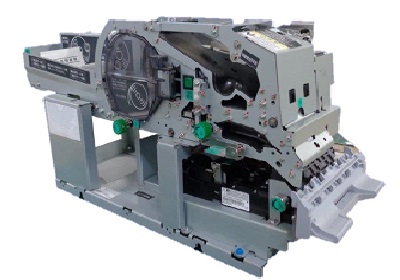

• Parts Assembly

- Cable / Wire Routing

- Sensor and Belt Adjustment

• Electrical Adjustment

• Function Test

Parts Manufacturing

WE DO DIE DESIGN AND FABRICATION. WE MANUFACTURE PRECISION PARTS SUCH AS PLASTIC MOLDING, SHEET METAL ( PRESS STAMPING AND NCT LASER), PRECISION SHAFTS/PINS AS WELL AS MECHANICAL ASSEMBLY PRODUCTS.

Count: 3

Count: 3

Count: 12

Count: 12

Count: 1

Count: 3

Count: 5

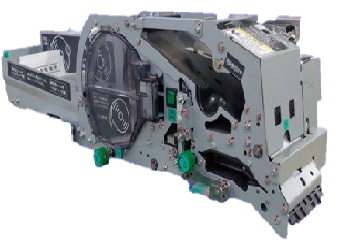

WE DO ASSEMBLY PRODUCTION OF MECHATRONICS PRODUCTS WITH HIGH QUALITY AND ON-TIME DELIVERY.

✓ WE ASSURE QUALITY OF PRODUCTS THROUGH THE USE OF ADVANCE MEASURING INSTRUMENTS.

✓ AUTOMATION FEATURES ALLOWS SPEED AND ACCURACY OF MEASUREMENT DURING INSPECTION.

Certifications

WE ARE ISO CERTIFIED!